Precision PCB Repair Service

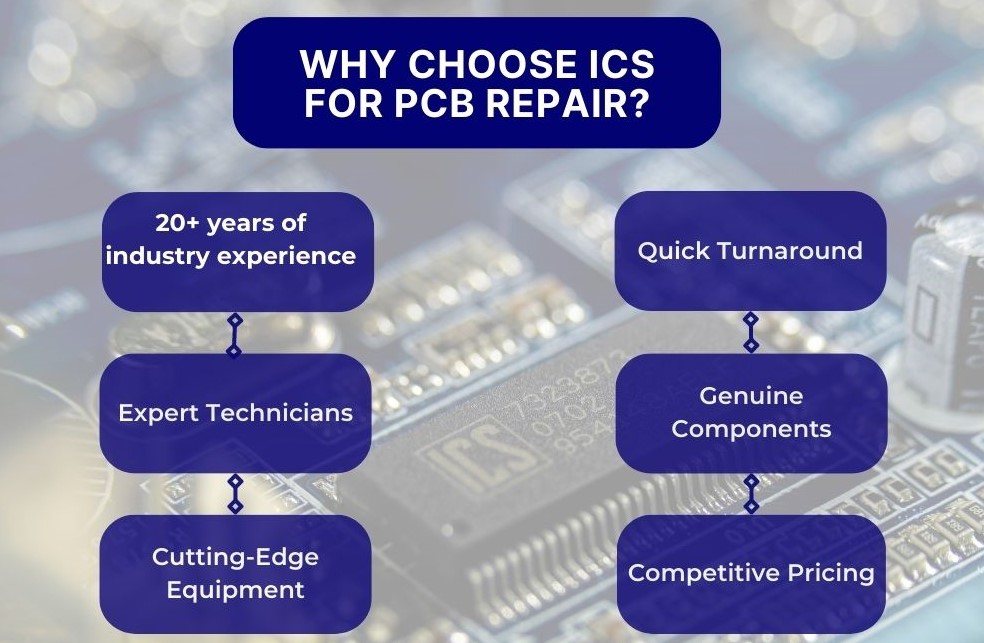

At Industrial Control Solutions, we take pride in our 20-plus years of experience in industrial repair, specializing in top-notch PCB board repair services. PCB boards are critical components in various industrial applications, and when they malfunction, it disrupts operations. Our skilled technicians are well-versed in diagnosing and resolving PCB board issues promptly. We ensure minimal downtime and maximum productivity for your business.

Our PCB Repair Services

- Printed Circuit Board (PCB) Repair;

- PCB Assembly Repair;

- PCB Component Repair;

- PCB Rework and Modification.

Electronic Circuit Board Repair Services are essential for addressing various types of damage that electronic circuit boards may encounter.

Common PCB Issues We Resolve:

- Physical Damage: This includes visible damage to the circuit board. Cracks, broken traces, or components knocked off the board due to impact or mishandling are a few examples.

- Burnt Components: Overheating can lead to components getting burnt or damaged, resulting in malfunctioning circuits and possible short circuits.

- Corrosion: Exposure to moisture or other corrosive elements can lead to oxidation and corrosion of circuit board components, causing connection issues and circuit failures.

- Solder Joint Failures: Solder joints that have cracked or come loose can cause intermittent connections or complete circuit failures.

- Electrical Overload: Power surges or voltage spikes can overwhelm the circuit board, damaging sensitive components and leading to circuit malfunctions.

- Environmental Damage: Exposure to extreme temperatures, humidity, dust, or contaminants can degrade the circuit board’s performance over time.

- ESD (Electrostatic Discharge) Damage: Static electricity discharge can harm sensitive electronic components, leading to circuit malfunctions or complete failure.

- Firmware or Software Issues: Faulty firmware or software updates can cause compatibility issues and disrupt the functionality of the circuit board.

- Manufacturing Defects: Circuit boards with manufacturing defects, such as incorrect component placements or inadequate soldering, can cause failures.

- Obsolete or Hard-to-Find Components: Aging or discontinued components on the circuit board may require expert sourcing or reengineering to replace them effectively.

- Design Flaws: In some cases, design flaws in the circuit board may lead to operational problems, requiring redesign or modification.

- Replacement: In cases where repairs are not viable, we offer efficient circuit board replacement services to get your equipment back up and running as quickly as possible.

Industrial Control Solutions Leads in PCB Repair Services

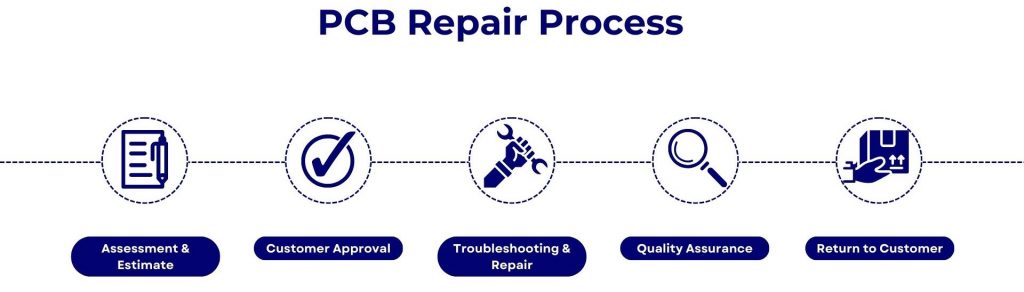

Professional Electronic Circuit Board Repair Services employ advanced diagnostic tools and techniques to identify the exact cause of the damage. Engineers perform precise repairs, including component replacement, soldering, trace repair, and testing to return the circuit board to optimal performance. With our 20 years of industrial repair experience and a strong customer base in the USA, we guarantee reliable and efficient repairs for your valuable PCB boards. Don’t let PCB board issues hamper your industrial processes; contact us now to schedule a repair service and experience the excellence of our PCB board repairs.

Affordable PCB Repair Cost

Worried about the cost? Rest assured, our PCB repair cost is competitive and tailored to suit your budget while maintaining the highest standards of quality.

Industrial Control Solutions is your trusted partner for expert PCB board repair services.

Have questions or need support? Don’t hesitate to contact us:

502-493-1352